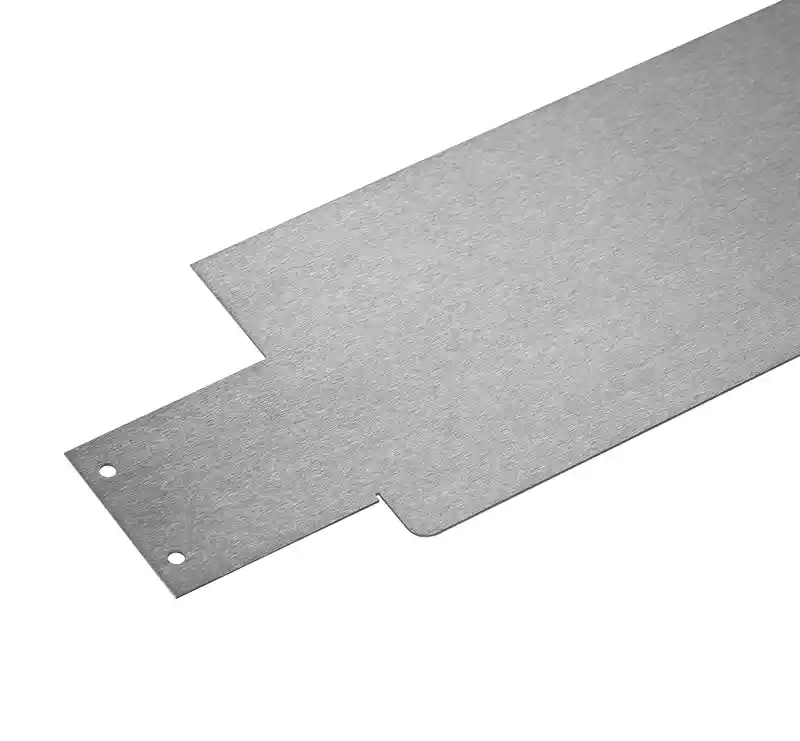

Deburring / Edge-rounding / Oxide removal / Deslagging / Hair-line

Materials:

Steel plate, stainless steel plate, aluminium plate, copper plate, titanium plate.

Applications:

Sheet metal

Punched parts

Semiconductor related parts

Architecture material

Machine structure

Ming Ping is a professional wet deburring machine manufacturer built up by a group of expert engineers and management of product.We have an experienced professional R&D team and professional instruments to keep the product quality at a high level. To offer flawless products, we continue to strengthen in-line quality control in particular, coupled with intensive personal training.

| Model | - | Working width |

|---|---|---|

| IUW | - | 610 |

| IUW | - | 915 |

| IUW | - | 1300 |

Standard

1. Control panel with push buttons.

2. Electric eye for sanding belt tracking.

3. Alarm bell and flash light.

4. Speed change for feeding, controlled by Inverter (VFD). *Feed speed: 3-15M/min.

5. Speed change for sanding and disc brush, controlled by Inverter (VFD).

6. PVC waterproof belt.

7. Automatic device for feed belt tracking.

8. Automatic to stop a machine when sanding belt off.

9. Pressure shoes: by rubber roller.

10. Water-cooling system (paper filter and air blower in the rear of the machine).

11. Separate electrical cabinet. Reduce liquid hazard on the electrical parts.

Option

(1) Magnetic filter.

(2) Magnetic table for ferrous material.

Download

Download